To help you better understand the process and provide you with insight you can use to easily apply the. Lean Six Sigma is simply a process of solving a problem that consists of five basic phases.

Is This A Six Sigma Lean Or Kaizen Project

Is This A Six Sigma Lean Or Kaizen Project

Lean Six Sigma Explained Simplilearn - YouTube.

Lean six sigma explained. The term Six Sigma refers to statistical quality control. Its tools and techniques are Lean and Six Sigmas best. Lean Six Sigma finds synergy between these two managerial styles.

Only 32 of QHSE professionals say they are using Lean Six Sigma Qualsys survey November 2018. Lean Six Sigma is a process that aims to systematically eliminate waste and reduce variation. Jack Welch made it central to his business strategy at General Electric in 1995.

Since then Lean Six Sigma has been used in a variety of economic sectors such as healthcare finance and supply chain. What is lean six sigma. Lean Six Sigma is a fact-based data-driven philosophy of improvement that values defect prevention over defect detection.

This 2 minutes animation gives you the basic understanding of this business process improvement method. The objective is to use the power of. A six sigma process is one in which 9999966 of all opportunities to produce some feature of a part are statistically expected to be free of defects.

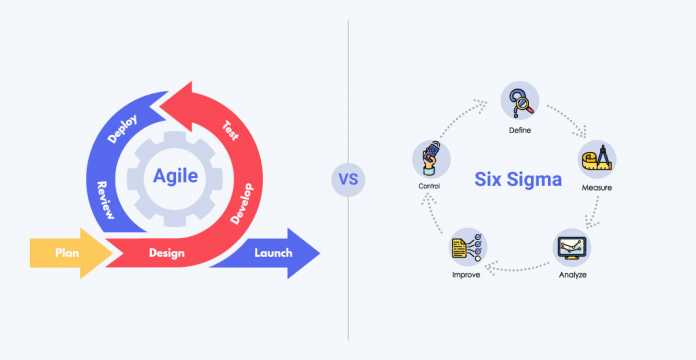

It drives customer satisfaction and bottom-line results by reducing variation waste and cycle time while promoting the use of work standardization and flow thereby creating a competitive advantage. Lean Six Sigma In 8 Minutes What Is Lean Six Sigma. Lean Six Sigma uses Six Sigmas define measure analyze improve control DMAIC system for process improvement.

What is Lean Six Sigma. Lean Six Sigma works toward driving customer satisfaction and emphasizes on the results by. Lean Six Sigma In 8 Minutes What Is Lean Six Sigma.

Lean Six Sigma Explained. DMAIC pronounced duh-may-ik which is an acronym for Define Measure Analyze Improve and Control the five phases of the Lean Six Sigma process. Lean six sigma is the amalgamation of 2 process improvement tools namely lean manufacturing and six sigma.

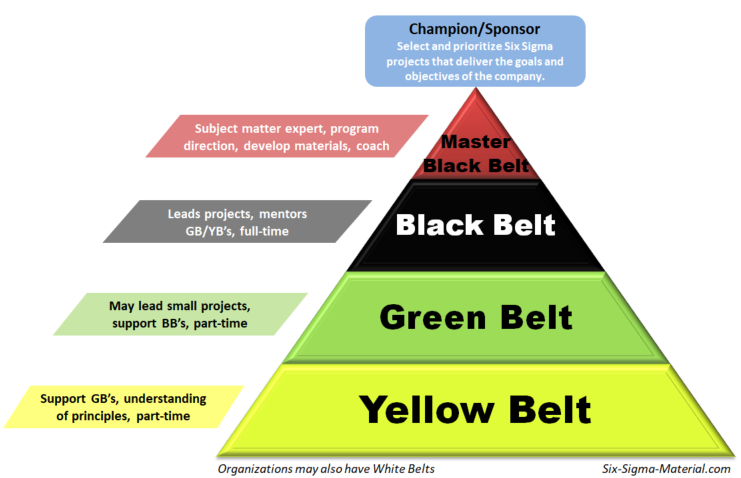

Lean Management seeks to reduce waste and thereby production cycle time whereas Six Sigma focuses on reducing variation among deliverables. Six Sigma 6σ is a set of techniques and tools for process improvementIt was introduced by American engineer Bill Smith while working at Motorola in 1986. What Is Lean Six Sigma.

All your team needs to do is choose the technique or tool that best fits their process improvement challenge. Training guide For complete beginners 2. Lean Six Sigma is a management theory centered on empirical evidence and centered on results which emphasizes avoidance of defects over-identification of defects.

Six Sigma ultimately uses data to produce products and results that are as perfect as possible since defective items lead to waste. Six Sigma improves on all business processes by eliminating waste and defects. Lean Six Sigma is a process improvement methodology designed to eliminate problems remove waste and inefficiency and improve working conditions to provide a better response to customers needs.

What is Lean Six Sigma. Learn more at wwwleansixsigm. The result is a hybridized system for making all aspects of a business run more effectively with increased profitability.

Lean focuses on eliminating eight areas of waste. Lean Six Sigma allows the use of multiple tools in every phase. Defects overproduction waiting non-utilized talent transportation inventory motion and extra-processing.

Lean six sigma explained. Overview Over the past few decades streamlining processes has been identified as the key to unlocking the maximum efficiency of a plant. A variation on the Six Sigma framework marries Lean Management principles with Six Sigma methodologies.

Lean Six Sigma takes the fundamental Six Sigma strategies for streamlining business processes and applies them alongside the lean strategies of product production.