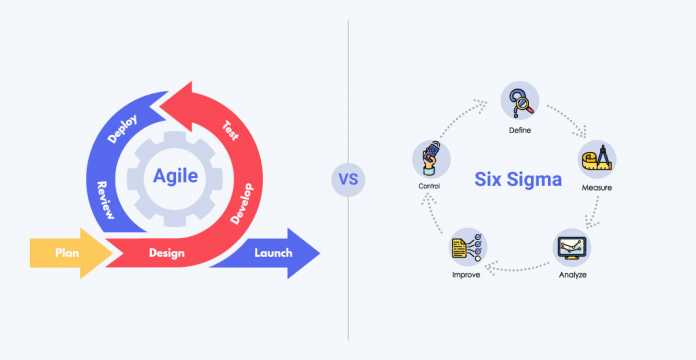

In essence Lean Six Sigma associates the devices systems and beliefs of Lean and Six Sigma within one popular and effective process for advancing your business operations. Six Sigma is ---Six Sigma is shorthand for a discipline that allows any business to design improve and manage its processes so that they perform at their highest possible levels.

6 Most Effective Lean Six Sigma Principles You Need To Know

6 Most Effective Lean Six Sigma Principles You Need To Know

Lean Six Sigma Green Belt Training Our Green Belt students recently presented the results of their Continuous Improvement projects to the management team in Dublin.

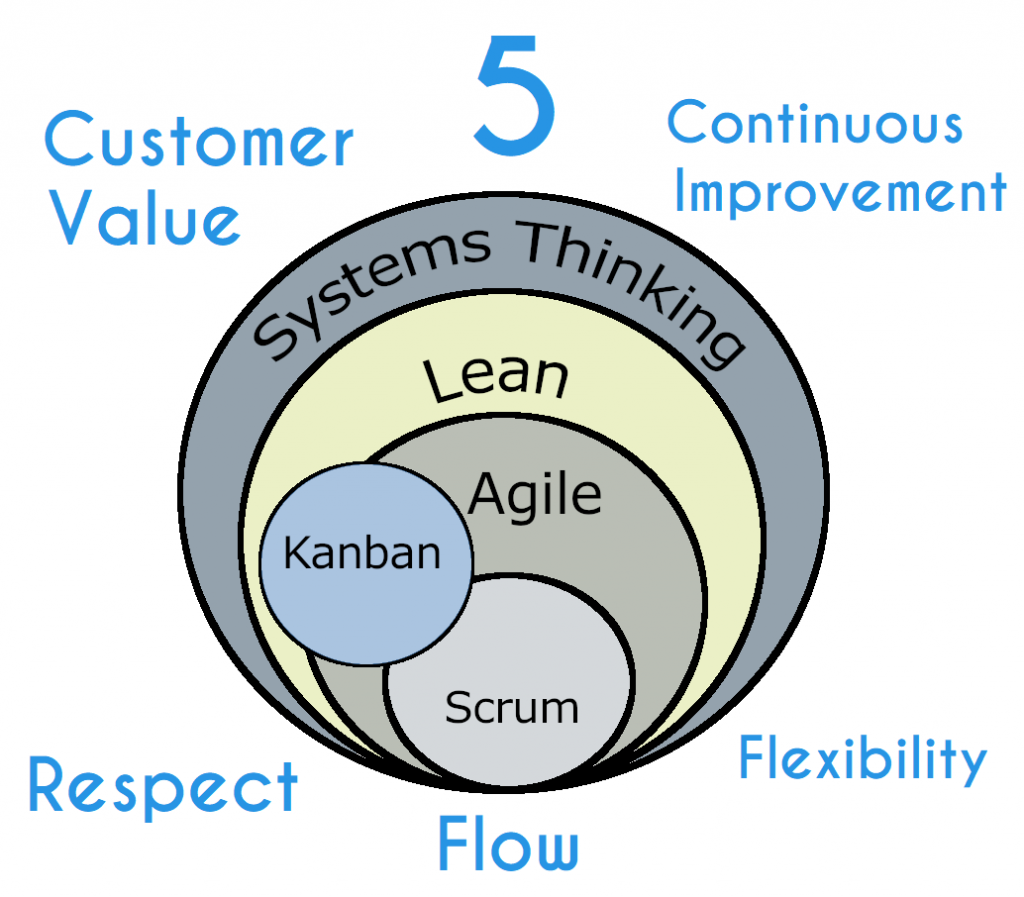

Lean six sigma principles. Lean Six Sigma is a powerful proven method of improving business efficiency and effectiveness. In order to compete for customers and market share many organizations are practicing Lean Six Sigma principles to improve operational effectiveness like reducing waste and. The discipline known as Lean Six Sigma LSS blends these two approaches.

High levels of performance mean high volume fast turnaround times very few errors or. ASQ American Society for Quality states Lean Six Sigma is a fact-based data-driven philosophy of improvement that values defect prevention over defect detection. This increases their effectiveness at delivering results for any improvement project they are involved in.

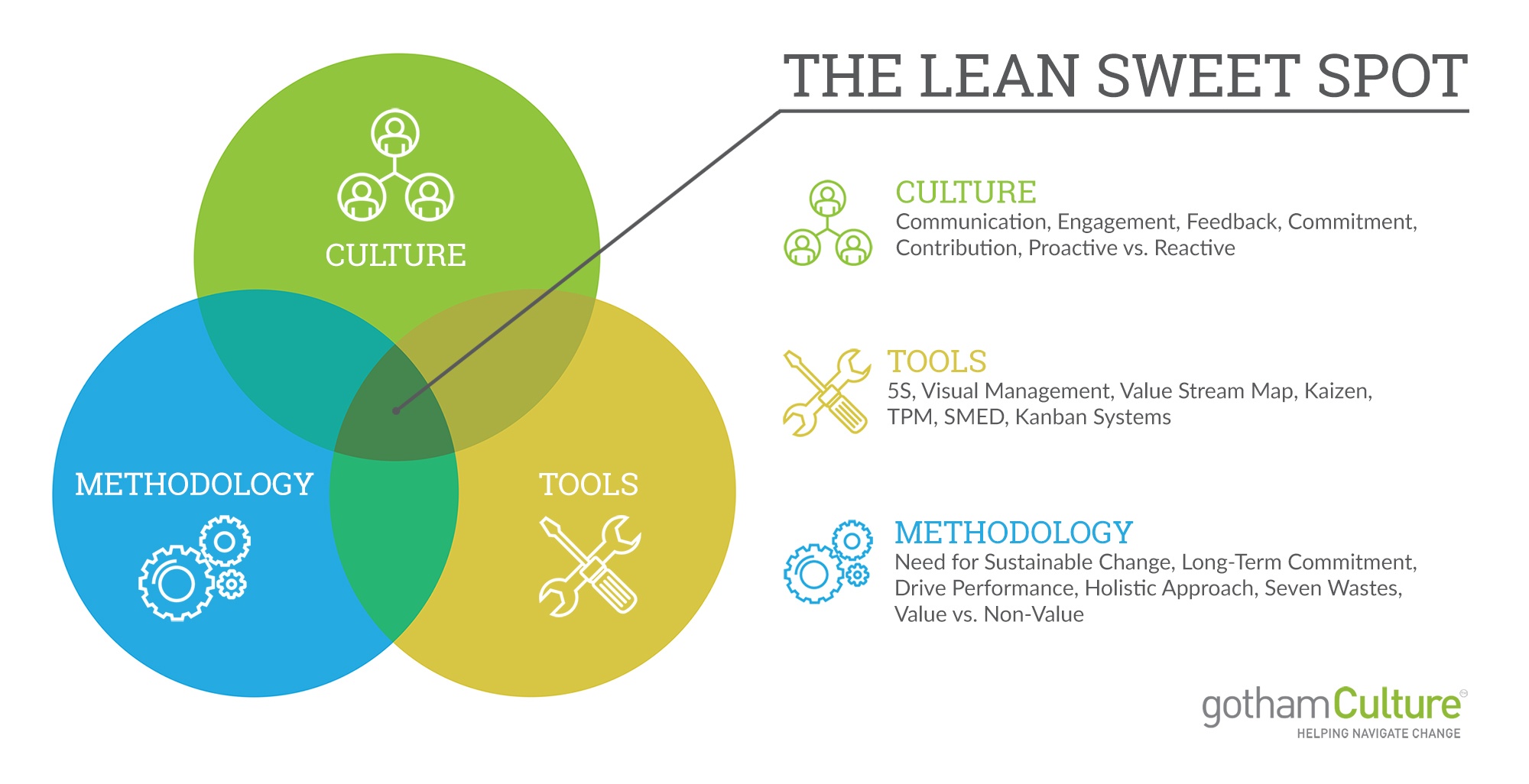

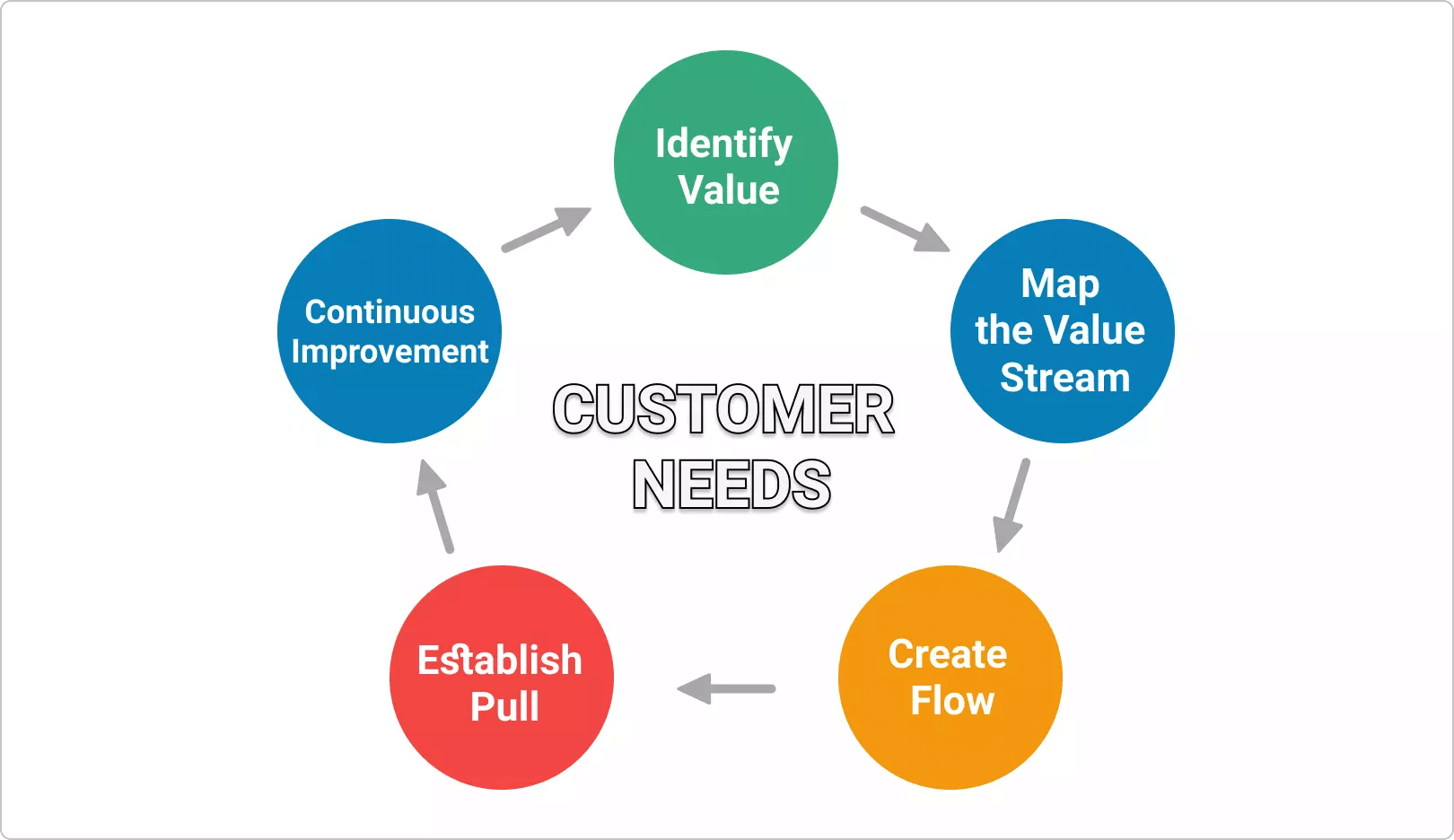

Quite often this benefit is overlooked by organizations who implement Lean Six Sigma but its underlying advantages dramatically increase the. The primary aim of the Lean method is to reduce waste. Lean Six Sigma is a process improvement methodology designed to eliminate problems remove waste and inefficiency and improve working conditions to provide a better response to customers needs.

In a nutshell here are the key principles of Lean Six Sigma Business Transformation to bear in mind. Focus on the customer. Concepts of Lean Six Sigma.

It drives customer satisfaction and bottom-line results by reducing variation waste and cycle time while promoting the use of work standardization and flow thereby creating a competitive advantage. These two approaches have been combined together to form an effective tool to enhance business processes. We currently have nine members of the team in Ireland training for Lean Six Sigma Green Belt accreditations with each member implementing improvement projects over the last year.

Well investigate the key Six Sigma principles which can shape and direct process improvement in your business. Basically Lean Six Sigma develops a sense of ownership and accountability for your employees. The methodologies of Six Sigma work with any system with a specified achievement goal and measurable components as it heavily relies on data.

The goal of Six Sigma is to reduce variation for optimal quality control. Lean Six Sigma is a fact-based data-driven philosophy of improvement that values defect prevention over defect detection. Identify and understand how the work gets done the value stream.

The core Six Sigma principles The 7 key Six Sigma principles well cover are. Refinements to the production process are essential to managing and reducing the 8 wastes analyzed by the Lean method. Always focus on the customer.