One of the main differences between the lean vs agile model is that the lean model focuses on the optimization of the production process whereas development comes first for the agile model. The two main tenents of agile are quick delivery of.

Incorporating Lean Methodologies In Agile Yodiz Project Management Blog

Incorporating Lean Methodologies In Agile Yodiz Project Management Blog

We will learn the basics of Agile and.

Lean agile methodology. Trusted by 45000 IT and non-IT companies. Ad Manage agile projects and knowledge base in one tool. You can deliver more value to your customers by following the lean methodology principles.

Start a trial today. Ad Powerful project management software for teams. Agile and Lean are two well-known techniques in the venture board world that assist groups with conveying quicker more feasible outcomes.

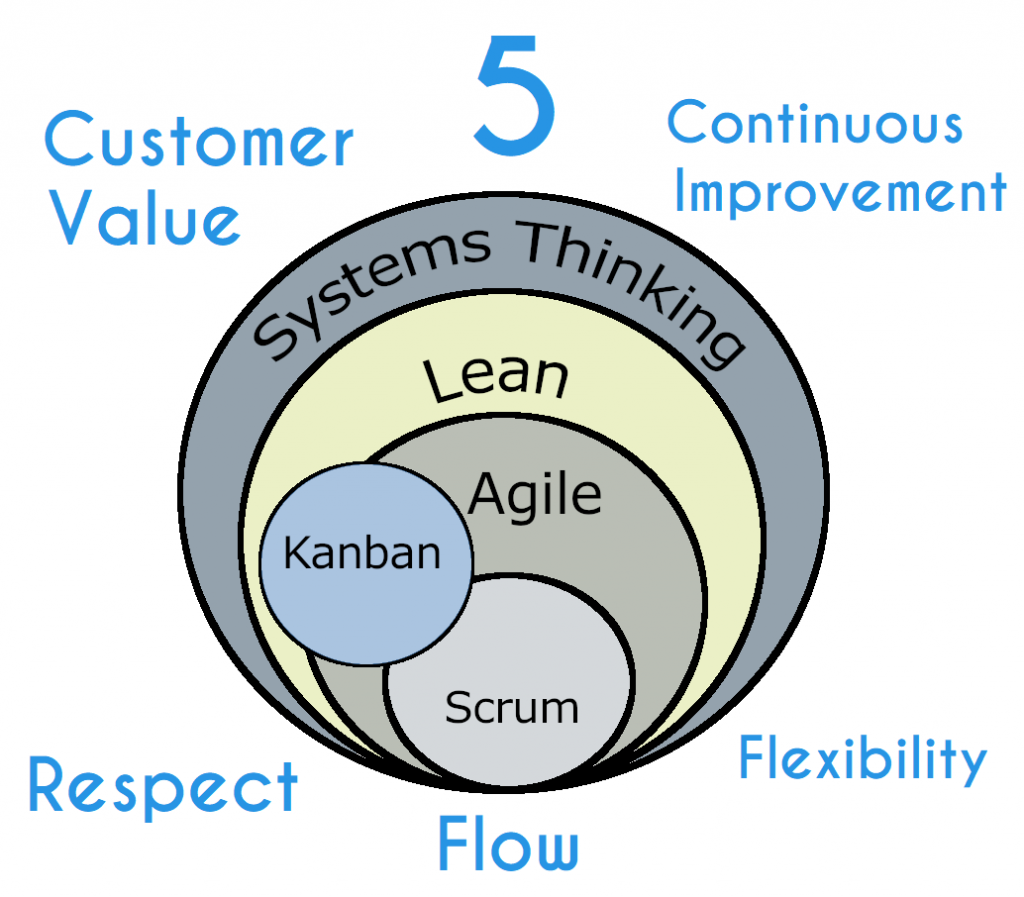

In theory lean and agile are different approaches. Read on to learn more about the important connection between Lean and. Lean Agile is a set of principles and practices for working that aims to minimize waste whilst maximizing value.

Trusted by 45000 IT and non-IT companies. Using Agile development methodologies can help your product become proactive instead of reactive and can mean the difference between success and failure in ever-changing environments. Lean Agile means doing less by adding the right.

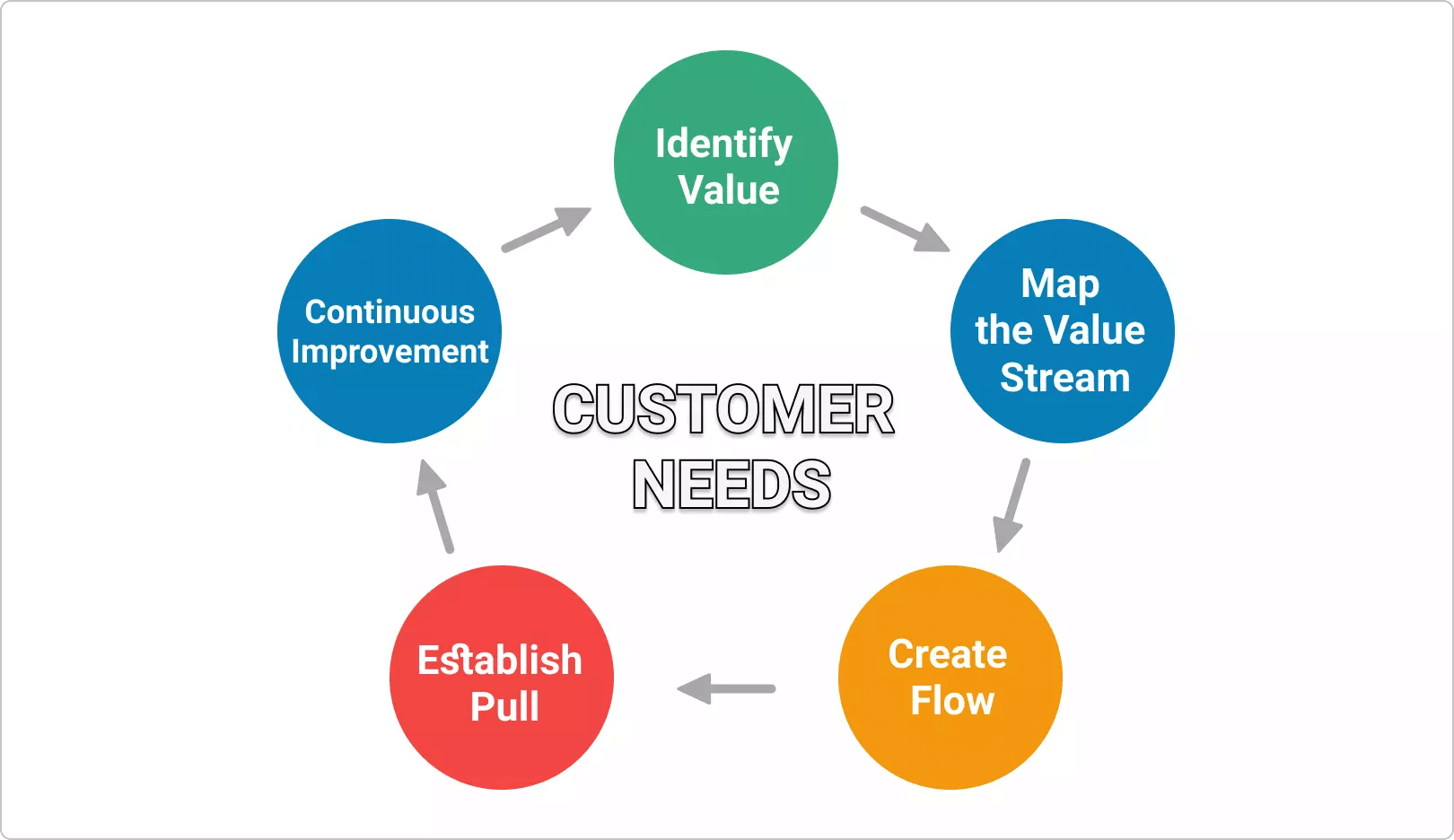

In reality its not a case of lean methodology vs agile instead lean is a type of agile practice. Agile and Lean methodologies are being called upon to help businesses move faster and produce higher quality offerings in sustainable healthy work environments. Lean methodology optimizes your organizations people resources effort and energy toward creating value for the customer.

Ad Manage agile projects and knowledge base in one tool. Designed for agile teams of all sizes. The Lean methodology relies on three straightforward ideas.

To make things much more convoluted numerous organizations embrace a Lean system when attempting to scale Agile over the. Lets look at what agile is before we jump to how to combine lean and agile. Measure performance report effectively get insights.

The main difference is that the Agile methodology concerns the optimization of a development process while the Lean method concerns the optimization of a production process. Agile development is a process for rapid software delivery that is connected to many Lean principles. Because they are implemented differently in different teams organizations and industries theres a lot of confusion about the distinctions between these methodologies and the practices associated with them.

Each sprint usually lasts for 2-4 weeks. Ad Powerful project management software for teams. In production we generally have a predefined product and we want to produce as many high quality products as possible in the most economic way possible.

When it comes to product development agile has been a favorite choice for creating workflows amongst many businesses. Unlike traditional project management methodology in the Agile approach a large project is broken down into shorter development cycles known as sprints. Designed for agile teams of all sizes.

Yes there was money and time involved as well but both lean and agile methodologies were created to make clients happy with the product as well as the process easier for the team members. Agile and Lean methodologies in software development enable teams to deliver faster. Agile is a software development methodology that helps develop projects with an iterative approach.

Lean-agile methodologies both focus on customer value As it often is and should be in the business world the customer or client was the main reason for both methodologies. The simple answer is this. The agile development process however focuses on enhancing.

But to truly unlock the power of Agile you need to pair it with Lean principles. In the lean production version a reworking of the differences of a product is predefined so that the product is produced economically. Measure performance report effectively get insights.

These two strategies frequently utilize the terms interchangeably while portraying regular practices. Agile Methodologies and Frameworks- Kanban and Lean Management This tutorial is about Agile Methodologies and Frameworks- Kanban and Lean Management of the PMI-ACP Certification course offered by Simplilearn. Deliver value from your customers perspective.

Start a trial today. A Lean Agile process has both elements of continuous delivery and continuous improvement.