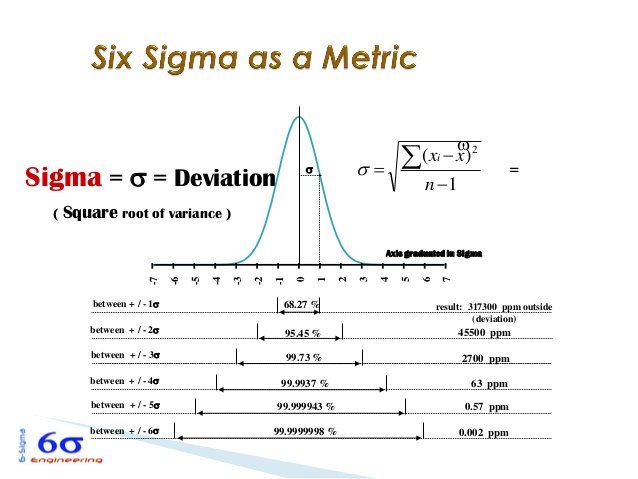

Since were working with data it is natural that we will work with statistics as you will learn in any reputable Six Sigma Green Belt trainingThere is one particular statistical term that is critical for Six Sigma and for understanding a process based on Six Sigma principles as briefly taught in free Six Sigma courses. Say you sold 1 million product out which 34 product are defect then you can say my process is Six Sigma or other words my company operate at six sigma level.

Lean Disciplines The 6 Sigma Methodology Synoptic Pages By Carlo Scodanibbio

Lean Disciplines The 6 Sigma Methodology Synoptic Pages By Carlo Scodanibbio

6 Sigma example Six Sigma is a disciplined statistical-based information-pushed method and non-stop development method for putting off defects in a product manner or service.

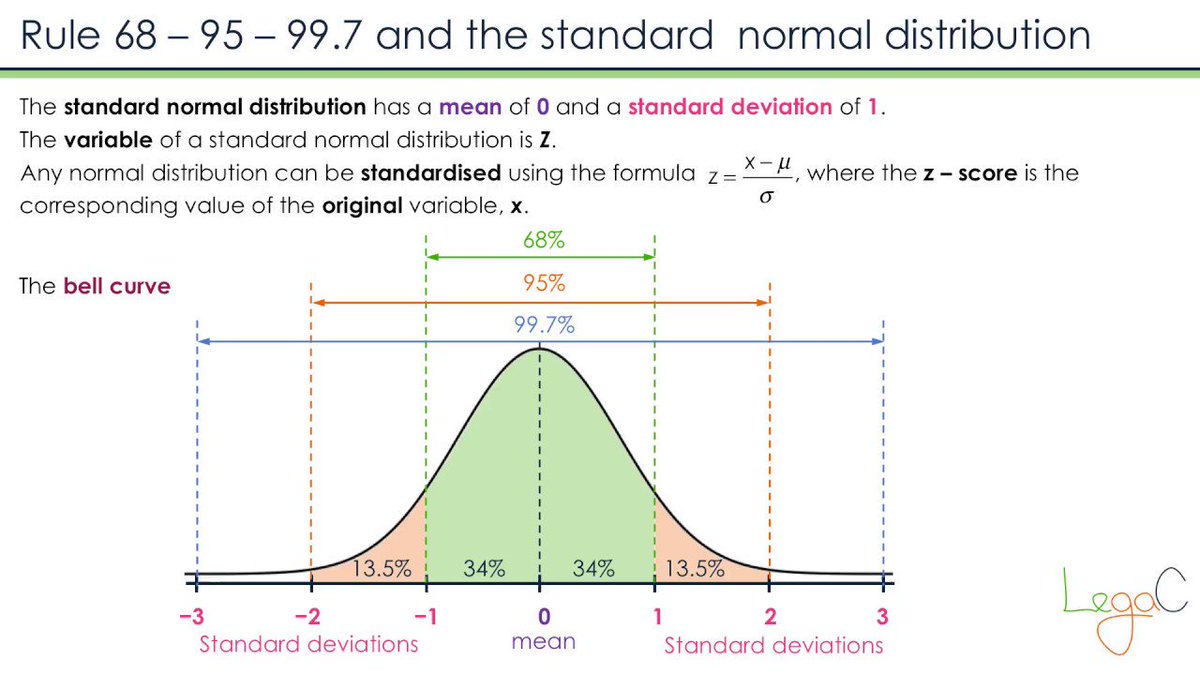

3 sigma vs 6 sigma. This is Three Sigma. Three sigma represents a deviation from the engineering standard of. The difference between three sigma and six sigma is what percentage of the total observations in a data set falls between the mean and the upper limit specified by the particular sigma value.

Discover the Differences between 3 Sigma vs. The Six Sigma approach is a data-driven approach to problem-solving. More specifically Three Sigma expects an error rate 668K errors per million.

A 2 sigma control limit therefore indicates the extent to which data deviates from the 95 probability and a 3 sigma control limit indicates the extent to which the defects deviate from the acceptable 1350 defects. In the above table you will observe that as the Sigma level increase the Defects decrease. To discover more information about this topic read through the connected lesson Six Sigma vs.

What I do n o t quite understand is mainly related to the fact that for a process to be under control the output is compared with the long-term plus and minus three sigma limits and observing an out of control event beyond these limits will then call for investigation possibly stopping the process trouble-shooting adjusting the. Sigma or standard deviation is a widely used measure of the variability inherent in a population or sample. If you get stuck on any of the quiz questions the lesson will help you determine the.

Another way to look at it is that we calculate 3 sigma control limits from the measured mean. But the specification limits are set by the customers tolerance for variation not calculated. 3 Sigma VS 6 Sigma Setiap memproses sesuatu dipastikan tidak akan sama persis baik prosesnya itu sendiri maupun hasil proses tersebut.

We want 6 sigma from the mean to be within the customer specification limits regardless of whether or not the process is under control. While both three sigma and Six Sigma are used as measures of quality in a manufacturing environment the difference is great. In contrast to Six Sigma quality the old Three Sigma quality standard of 9973 translates to 2700 PPM failures even if we assume zero drift.

For example for a 2σ process the Defects are as high as 308537 in one million opportunities. 3 sigma used for a state of a process and 6 sigma constitutes a methodology. 6 Sigma in a different way Three Sigma is used to determine the state of a process while Six Sigma constitutes a methodology to set and achieve targets for quality outcomes.

Common probability dictates that 9973 of all outcomes will fall within 3 standard deviations of the mean above or below. The most noticeable difference is that Three Sigma has a higher tolerance for defects in comparison to Six Sigma. Same goes for 4 Sigma as 6200 defect in million 3 Sigma as 67000 defect in million 2 sigma as 310000 defect in.

Fourth calculate three-sigma which is three standard deviations above the mean. The most noticeable difference is that Three Sigma has a higher tolerance for defects in comparison to Six Sigma. Control Charts based on 3 Sigma Limits Additional 11172008.

So the standard deviation 02564 05064. In statistical control 1 sigma is the lowest sigma and 6 sigma the highest. Misalnya untuk memproses sesuatu kita butuhkan panas tekanan kecepatan voltase listrik atau lainnya.

With the aid of using three for this reason three-sigma and in the end subtract that product from the common of the whole series. If its 230 defect in million then your company is at 5 Sigma level. Similarly for a 6σ process the Defects is as low as 34 in one million opportunities.

For processes with a series of steps the overall yield is the product of the yields of the different steps. Summarizing 3 Sigma vs. In numerical format this is 3 x 05064 934 109.

Six Sigma Levels Of Sigma Processes

Six Sigma Levels Of Sigma Processes

Kirk Borne On Twitter What Does 2 Sigma 3 Sigma 5 Sigma 6 Sigma Etc Mean In Science Engineering And Quality Assurance Https T Co Iw7iobqnpt Datascience Statistics 6sigma Sixsigma Qualitymanagement Https T Co 2j8nymu2bq

Kirk Borne On Twitter What Does 2 Sigma 3 Sigma 5 Sigma 6 Sigma Etc Mean In Science Engineering And Quality Assurance Https T Co Iw7iobqnpt Datascience Statistics 6sigma Sixsigma Qualitymanagement Https T Co 2j8nymu2bq

Lean Six Sigma Continuous Improvement 3 Sigma Vs 6 Sigma

Lean Six Sigma Continuous Improvement 3 Sigma Vs 6 Sigma

Six Sigma Levels Of Sigma Processes

Six Sigma Levels Of Sigma Processes

Kirk Borne On Twitter What Does 2 Sigma 3 Sigma 5 Sigma 6 Sigma Etc Mean In Science Engineering And Quality Assurance Https T Co Iw7iobqnpt Datascience Statistics 6sigma Sixsigma Qualitymanagement Https T Co 2j8nymu2bq

Kirk Borne On Twitter What Does 2 Sigma 3 Sigma 5 Sigma 6 Sigma Etc Mean In Science Engineering And Quality Assurance Https T Co Iw7iobqnpt Datascience Statistics 6sigma Sixsigma Qualitymanagement Https T Co 2j8nymu2bq

Statistical Six Sigma Definition

Statistical Six Sigma Definition

Comparison Between Six Sigma And Three Sigma For Reducing Variability Download Scientific Diagram

Comparison Between Six Sigma And Three Sigma For Reducing Variability Download Scientific Diagram

Three Four Five And Six Sigma Processes For Our Laboratory Example Download Scientific Diagram

Three Four Five And Six Sigma Processes For Our Laboratory Example Download Scientific Diagram

Six Sigma Lean Manufacturing And Six Sigma Definitions

Six Sigma Lean Manufacturing And Six Sigma Definitions

3 Sigma Vs 6 Sigma Sigma Global Delhi Ncr

3 Sigma Vs 6 Sigma Sigma Global Delhi Ncr

Lean Six Sigma Continuous Improvement 2017

Lean Six Sigma Continuous Improvement 2017

No comments:

Post a Comment

Note: only a member of this blog may post a comment.