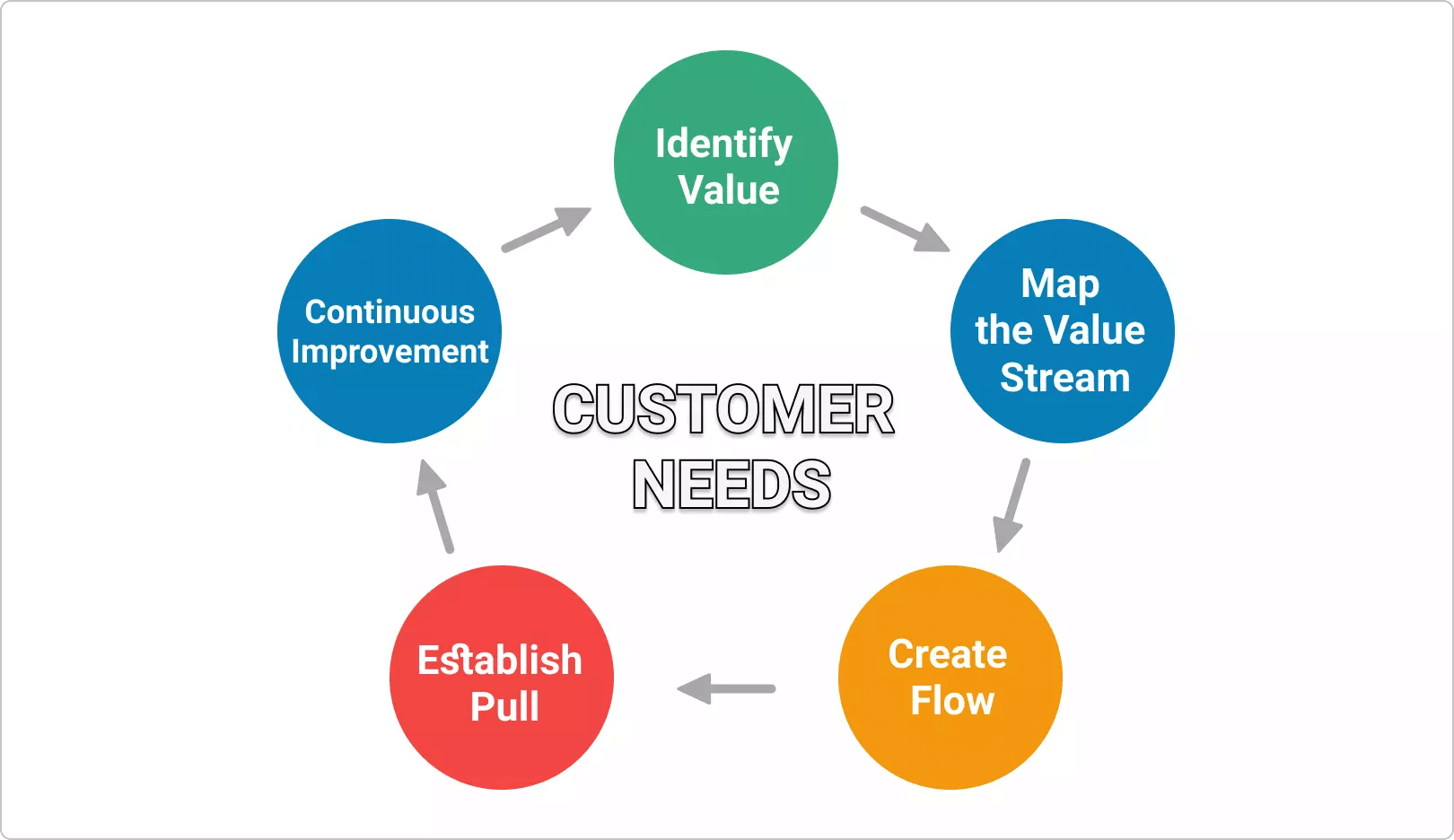

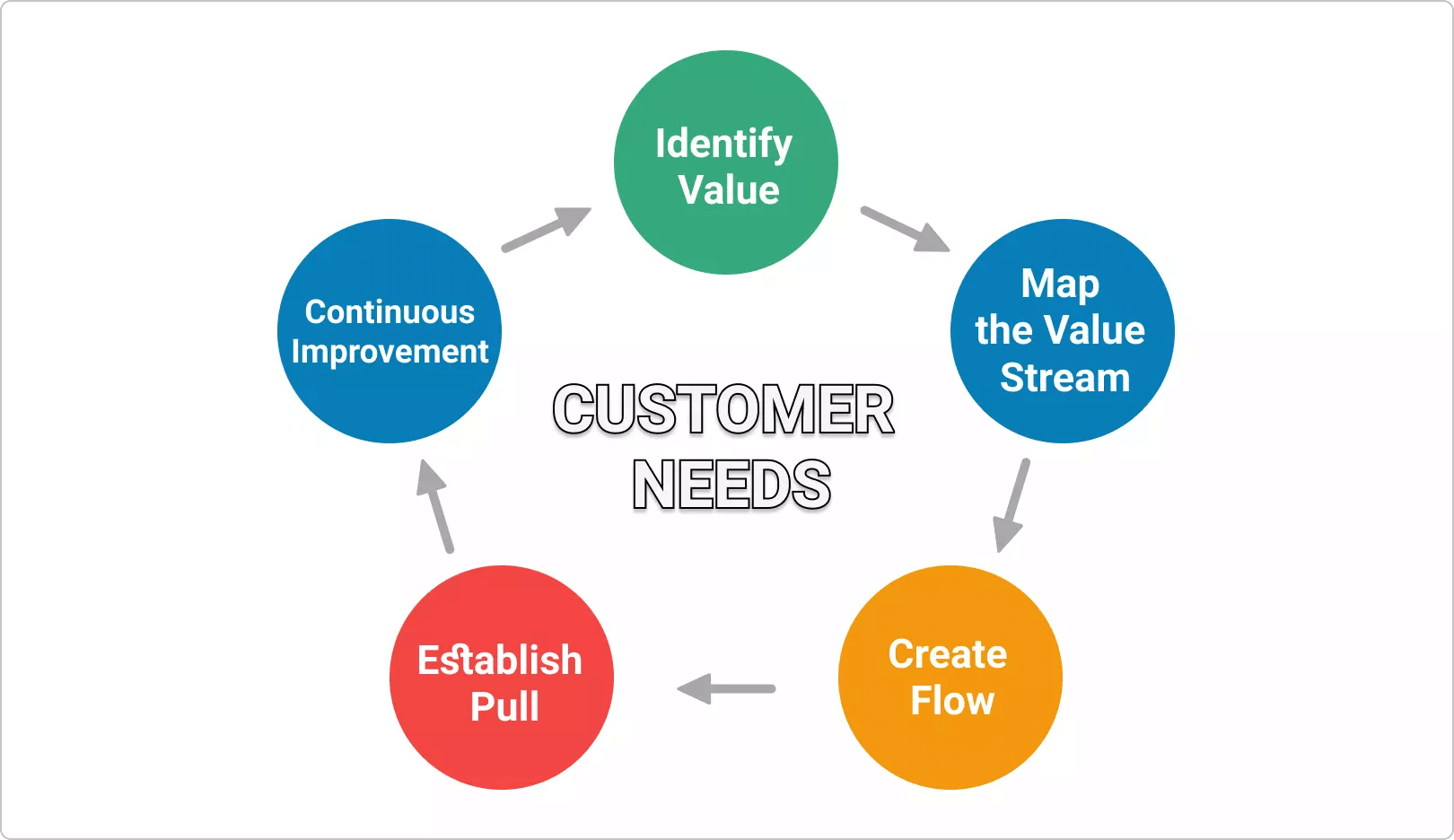

Lean Project Management focuses on eliminating wastes both in short term and long term to make process improvements which result in meeting the customer requirements effectively and accurately. Front-line workers should be involved in VSM activities.

Lean Methodology In A Nutshell Fourweekmba

Lean Methodology In A Nutshell Fourweekmba

As a philosophical approach Lean methodology enjoys broad applicability to processes within businesses of any size because of its ability to help organizations achieve business goals in a healthier smarter more.

Lean methodology focuses on. Waste is seen as anything that customers do not believe adds value and are not willing to pay for. The ultimate goal is to provide perfect value to the customer through a perfect value creation process that has zero waste. A lean organization understands customer value and focuses its key processes to continuously increase it.

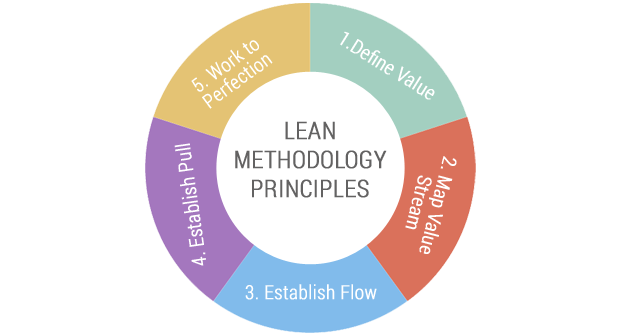

Lean management was created by Toyota in Japan and introduced into its factories in the 1970s. It combines the tools methods and principles of Lean and Six Sigma into one popular and powerful methodology for improving your organizations operations. Jones to capture the essence of their in-depth study of Toyotas fabled Toyota Production System.

Jone and Lean Thinking 1996 by James P. In short Lean methodology is a way of optimizing the people resources effort and energy of your organization toward creating value for the customer. The Lean methodology is an evolution of the Toyota Production System that the Japanese automaker implemented following World War II to improve the efficiency and flexibility of its manufacturing.

Womack Daniel Roos and Daniel T. Lean methodology continues to be popular with businesses due to its focus on reducing waste and improving efficiency in the interest of providing more value to customers. A Focus On Employees and Efficiency.

Although lean methodology came into existence through a manufacturing process it can be used in different business processes and technical processes as well. Lean can be focused on specific processes or cover the entire supply chain. Butcher on the bio on her website says she is comfortable dealing with workers at all levels.

It emphasizes removing wasteful steps in a process and taking the only value-added steps. Mainly used in the automotive industry Lean management is a way of thinking and acting that can be applied to all types of businesses industries and services. Lean thinking is a transformational framework that aims to provide a new way to think about how to organize human activities to deliver more benefits to society and value to individuals while eliminating waste.

She believes that Lean methodology can empower workers and make their jobs better in addition to helping the company overall. It is based on two guiding tenets continuous improvement and respect for people. We can define Lean as a system for developing process improvement that is continuous and has a focus on reducing and eliminating waste.

Here the main focus is on eliminating the waste processes to optimize. Implementing a series of small improvements incrementally along the supply chain can bring forth enhanced productivity. Toyota developed the concept to help with their production operation and improve processes to cut the time it takes from receiving an order to delivering it.

You minimize waste when you use a Lean approach. Womack and Daniel T. The methodology of Lean focuses on creating value at every level which builds overall value for your company and when done correctly can be transformational.

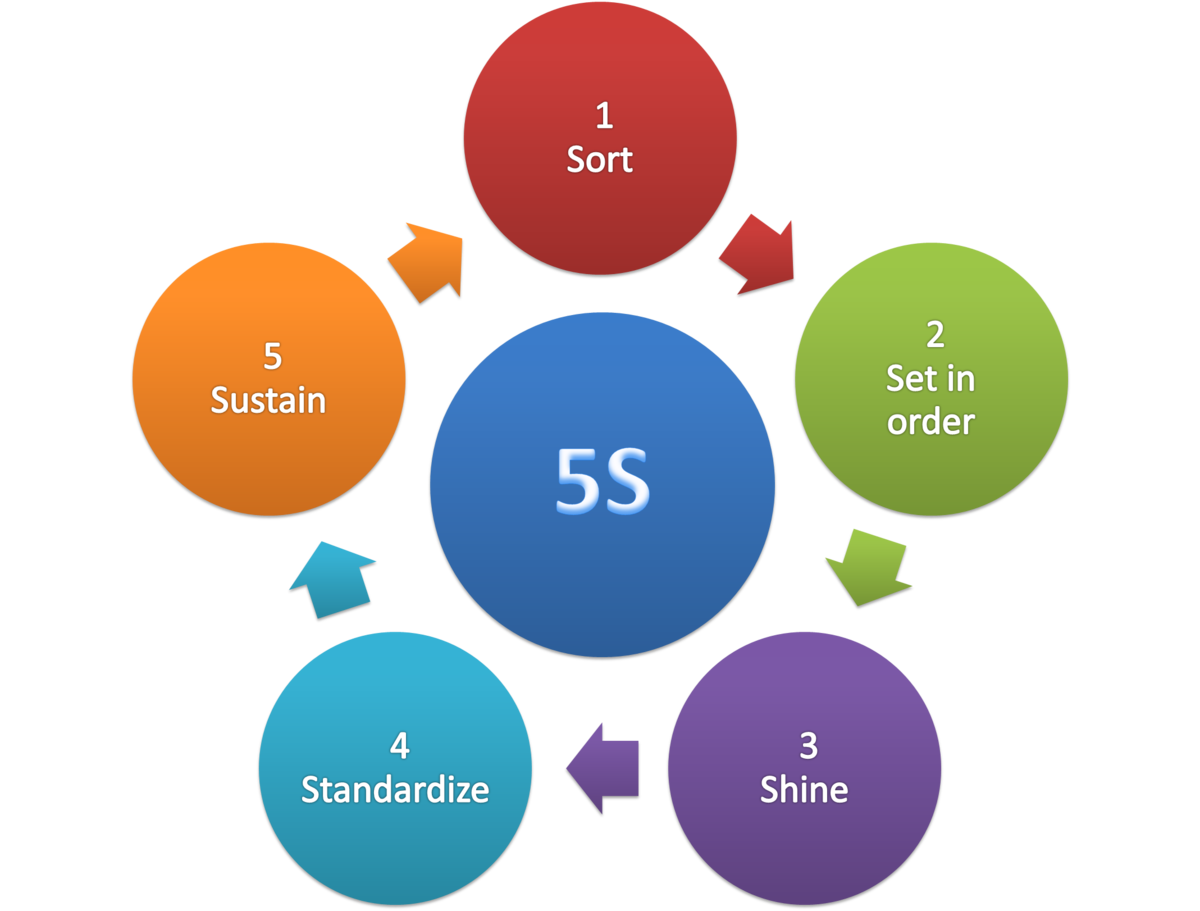

To eliminate the uselessness or the in the process companies leverage the various lean tools and principles. Lean manufacturing is a methodology that focuses on minimizing waste within manufacturing systems while simultaneously maximizing productivity. Two important books The Machine That Changed the World 1990 by James P.

The term lean thinking was coined by James P. For application of Lean to services rather than manufacturing see Lean Services. In her interview with Nooga she addressed the concerns some feel about Lean.

The Lean method ensures high quality and customer satisfaction. Lean Six Sigma is a process improvement methodology designed to eliminate problems remove waste and inefficiency and improve working conditions to provide a better response to customers needs. It is a methodology that focuses on lean management.

Through Lean it is possible to have better products made in a shorter time and at lower costs. Lean Project Management provides insight for all levels of the organizations rather than a specific department like software development. Lean is a systematic approach to reduce or eliminate activities that dont add value to the process.

The Basics Of Lean Methodology Video Included By Bogdan Deris Linkedin

The Basics Of Lean Methodology Video Included By Bogdan Deris Linkedin

Lean Methodology Vs Six Sigma Methodology

Lean Methodology Vs Six Sigma Methodology

What Is Lean Management Definition Benefits

What Is Lean Management Definition Benefits

The Lean Methodology In Project Management Infinity

The Lean Methodology In Project Management Infinity

What Is Lean Six Sigma What It Is Why It Matters How To Do It Right

What Is Lean Six Sigma What It Is Why It Matters How To Do It Right

Incorporating Lean Methodologies In Agile Yodiz Project Management Blog

Incorporating Lean Methodologies In Agile Yodiz Project Management Blog

.jpg) A Brief Introduction To Lean And Six Sigma And Lean Six Sigma

A Brief Introduction To Lean And Six Sigma And Lean Six Sigma

How Lean And Agile Relate And How You Can Win By Using Both Plutora

How Lean And Agile Relate And How You Can Win By Using Both Plutora

How To Attain Quick Wins In Supply Chain Cost Reduction Using Lean Logistics Bureau

How To Attain Quick Wins In Supply Chain Cost Reduction Using Lean Logistics Bureau

5 Ways Lean Methodology Drives Innovation Rever

5 Ways Lean Methodology Drives Innovation Rever

What Is Lean Management Definition Benefits

What Is Lean Management Definition Benefits

No comments:

Post a Comment

Note: only a member of this blog may post a comment.