Six Sigma is a data-based methodology to improve performance by reducing variability. It can also be used to bring breakthrough improvements.

How Do The Six Sigma Statistics Work

How Do The Six Sigma Statistics Work

Ad Search Faster Better Smarter Here.

What does six sigma mean. What Is Six Sigma. Ultimately reduces process costsB. Six Sigma is a set of methods and tools for process improvement.

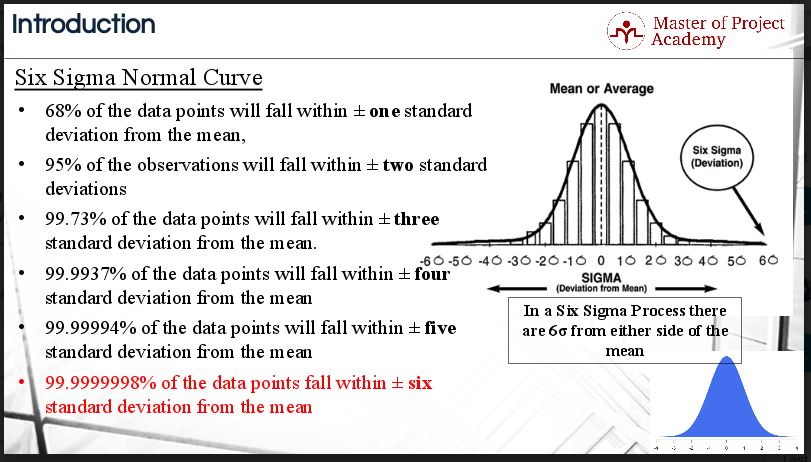

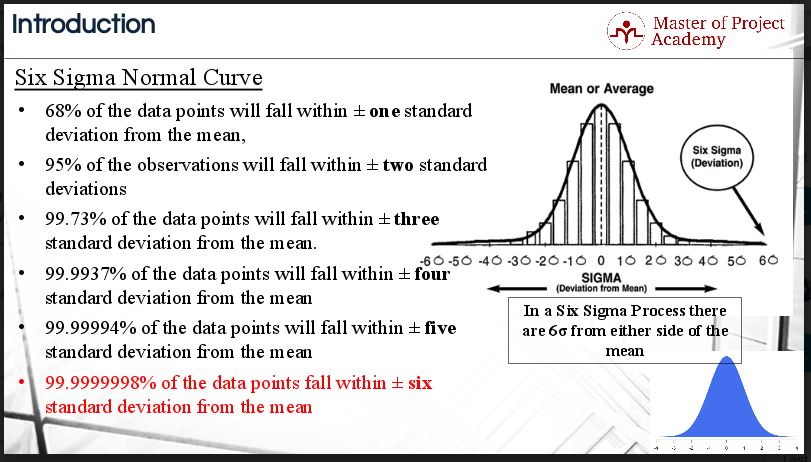

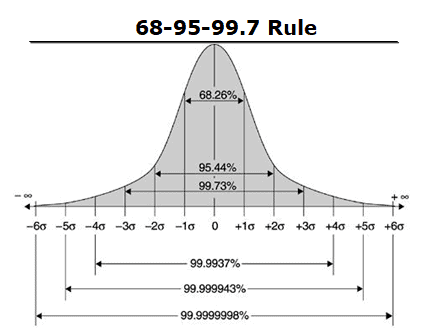

Six Sigma is defined as a measure of quality that organizations strive to achieve. Is a statistical concept that seeks to find variation in processesE. The name Six Sigma refers to the Greek letter sigma which is used in statistics to denote deviation from a mean.

Is a methodology for process improvementD. Companies and individuals are using six sigma methodologies to improve operational efficiencies. The method uses a data-driven review to limit mistakes or defects in a corporate or business.

Specification Limits are derived from the customer requirements and they specify the minimum and maximum acceptable limits of. Developed in 1986 Six Sigma has become a global phenomenon with companies around the world. What does six sigma mean.

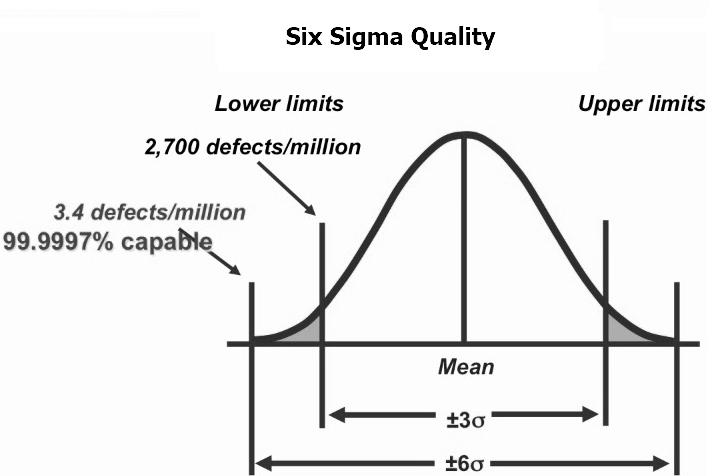

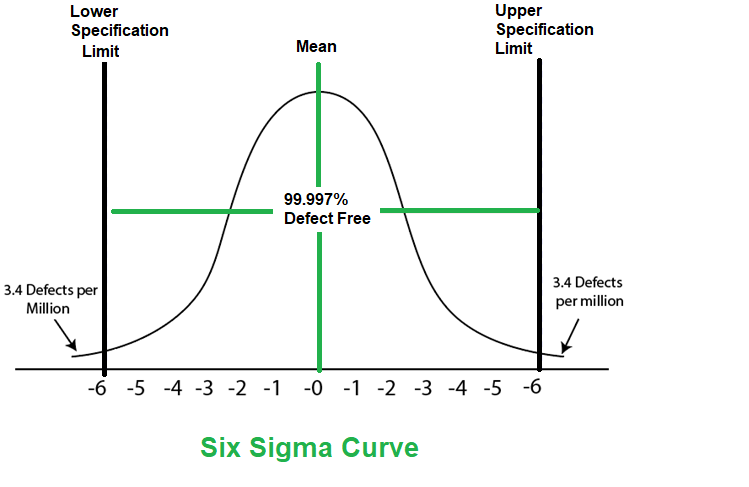

In other words it is a methodology to achieve 34 defects per million opportunities. Meaning of six sigma. Decreases customer satisfactionC.

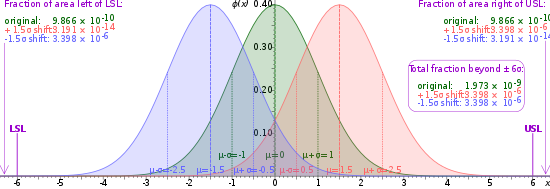

The key goal of Six Sigma is to streamline business processes by decreasing defects variations and wastes in a product or service at the same time improving employee morale and quality of products. Information and translations of six sigma in the most comprehensive dictionary definitions resource on the web. The 15 Sigma Shift Experience has shown that processes usually do not perform as well in the long term as they do in the short term.

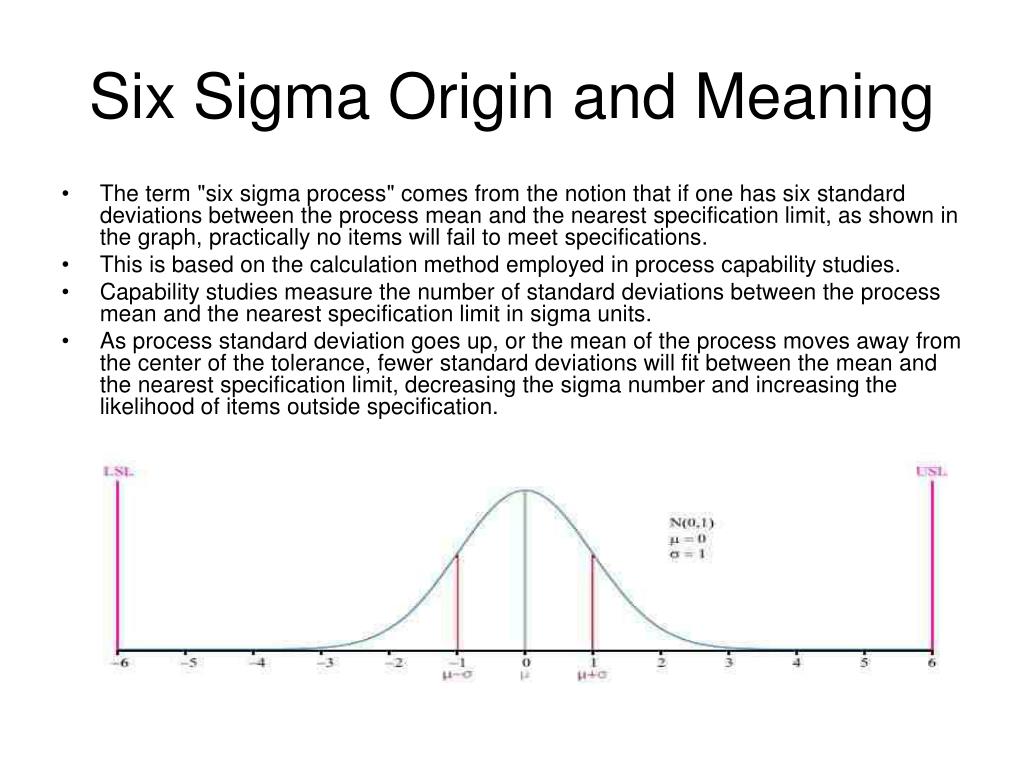

Six Sigma is a quality-control methodology developed in 1986 by Motorola Inc. Etymology of a Six Sigma Process The term six sigma process comes from the notion that if one has six standard deviations between the process mean and the nearest specification limit 12. The doctrines original goal was to improve any process to which it was applied such that defects would arise in no more than 34 in 1 million opportunities an accuracy rate of 9999966 and a defect rate per million.

Six Sigma is a disciplined data-driven approach and methodology for eliminating defects driving toward six standard deviations between the mean and the nearest specification limit in any process from manufacturing to transactional and from product to service. You may refer to few images like following. All of the above View Answer Answer.

Sigma in six sigma is simply the standard deviation 6 sigma means the process with must be 6 SD to ensure 99 data points or process points to say simply fall with in the customer specs. LSL and USL stand for Lower Specification Limit and Upper Specification Limit respectively. It requires thorough understanding of product and process knowledge and is completely driven by customer expectations.

Six Sigma stands for 6 standard deviations 6σ between avarage and acceptable limits. Six Sigma does not refer to a process operating within 6 or 45 standard deviations of the desired state. Ad Search Faster Better Smarter Here.

It is a disciplined data-driven approach used to eliminate defects in any process from manufacturing to transactional and from product to service. What does the Six Sigma meanA. Six Sigma provides qualitative tools to improve the capability of business processes.

What Is Six Sigma Vskills Blog

What Is Six Sigma Vskills Blog

Six Sigma In Software Engineering Geeksforgeeks

Six Sigma In Software Engineering Geeksforgeeks

Six Sigma Mad Management Skills

Six Sigma Mad Management Skills

What Is Six Sigma What You Need To Know To Pass Your Certification

What Is Six Sigma What You Need To Know To Pass Your Certification

Understanding Process Sigma Level Process Central

Understanding Process Sigma Level Process Central

Six Sigma Lean Manufacturing And Six Sigma Definitions

Six Sigma Lean Manufacturing And Six Sigma Definitions

Ppt Six Sigma Powerpoint Presentation Free Download Id 189945

Ppt Six Sigma Powerpoint Presentation Free Download Id 189945

Usage And Importance Of Statistics In Six Sigma Asklean

Usage And Importance Of Statistics In Six Sigma Asklean

Six Sigma Lean Manufacturing And Six Sigma Definitions

Six Sigma Lean Manufacturing And Six Sigma Definitions

Introduction To Lean Six Sigma Prodemyasia Com

Introduction To Lean Six Sigma Prodemyasia Com

Statistical Six Sigma Definition

Statistical Six Sigma Definition

No comments:

Post a Comment

Note: only a member of this blog may post a comment.