The Lean methodology reduces costs making it an effective tool against relocation. System and Process Design.

The Lean Methodology In Project Management Infinity

The Lean Methodology In Project Management Infinity

Thin especially healthily so.

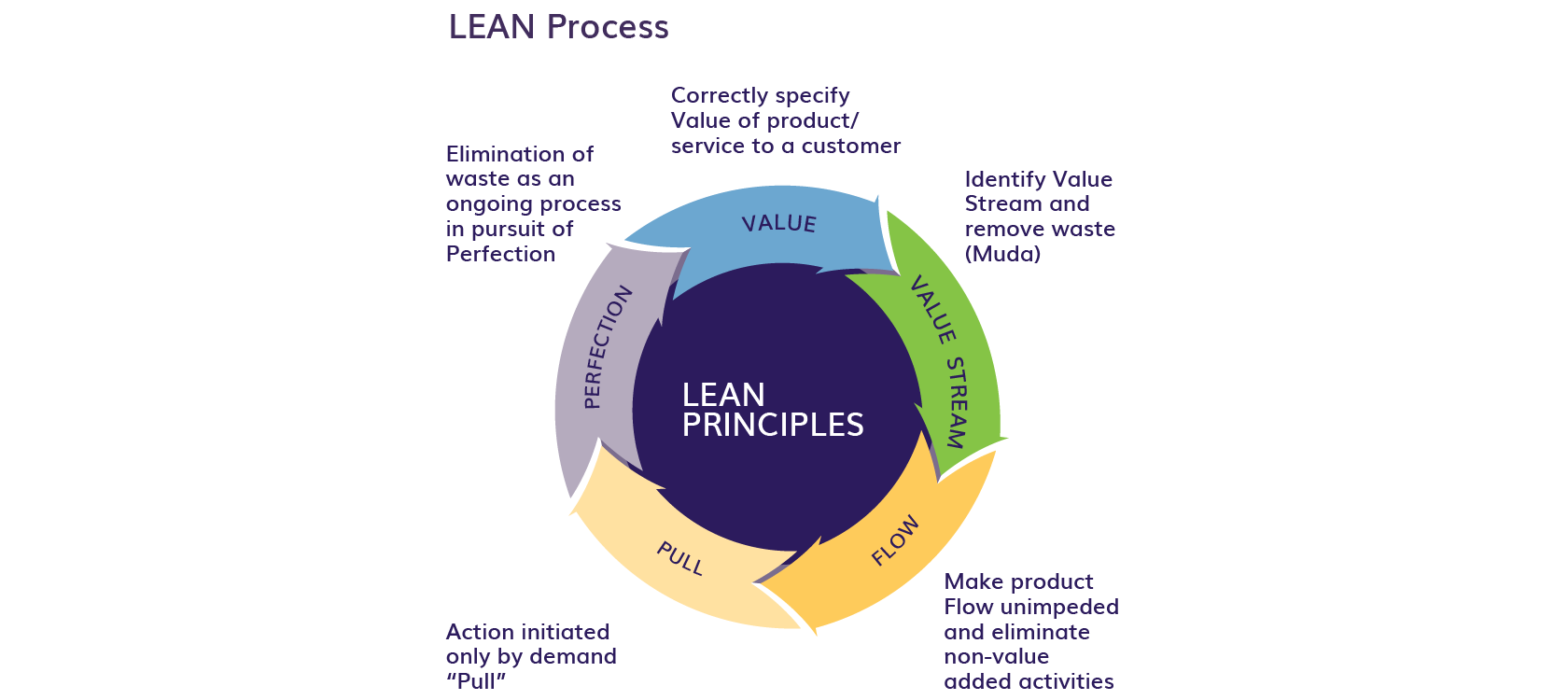

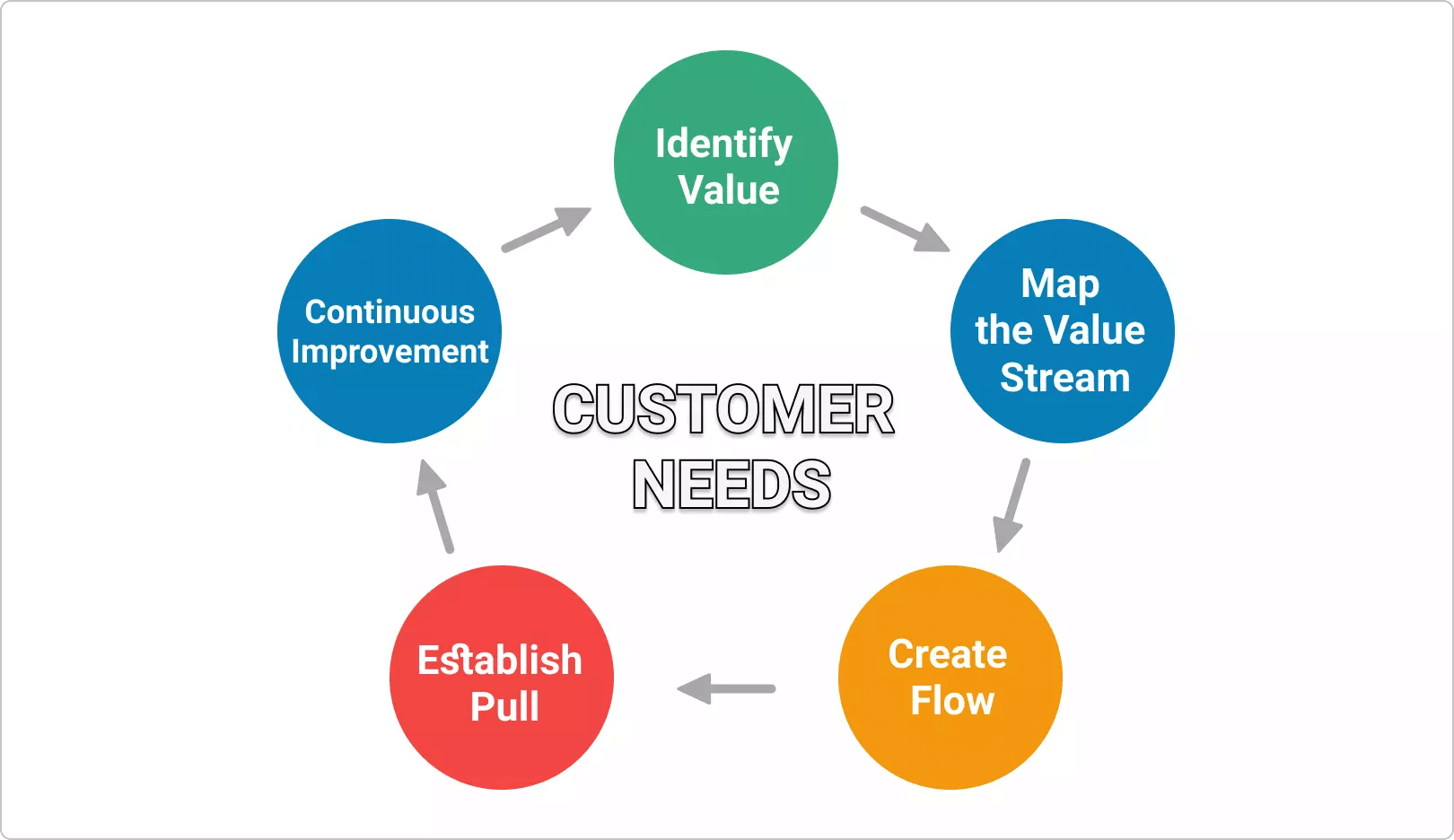

Lean process management. Process Management Applications. Lean management principles aims to create a stable workflow based on actual customers demand. Lean management has a positive impact on the well-being of employees who work differently and are subject to less stress.

Lean management principles focus teams on driving continuous improvement. This includes Design Modelling Implementation Monitoring and Optimisation. When a process consists of just one person doing one activity.

To accomplish this lean thinking changes the focus of management from optimizing separate technologies assets and vertical departments to optimizing the flow of products and services through entire value streams that flow horizontally across technologies assets and departments to customers. To increase our efficiency. Moreover including them in the improvement process is valuable to them and allows raising points that the management had not seen.

Business Process Management or BPM is a well-known methodology to manage processes and workflows in an organisation. Lean management involves a lot of process examination the addition of perspectives from various leaders in the organization and mapping the processes that are adding to the company. The main thing to remember.

When Lean is implemented effectively teams and the processes they use to deliver value to customers grow stronger over time. From a process perspective inefficiency is superfluous fat. What is Lean Management Lean management is a concept an approach to running a company by bringing exceptional value to your customers via continuous improvement.

Strategy for Systems Integration. Having no superfluous fat. Our in-house experts inject automation to this methodology or what they call Business Process Management Solution.

We can define Lean as a system for developing process improvement that is continuous and has a focus on reducing and eliminating waste. Method for Institutionalizing Continuous Improvement. Processes People Technology.

Lean process management is a strategy for business process improvement. Lean management refers to a technique developed with the aim of minimising the process waste and maximising the value of the product or service to the customer without compromising the quality. Fundamentally the process of successful lean transformation rests on applying PDCA cycles of experimentation the art and craft of science at every level everywhere all the time.

Being situational means that every story is going to be specific and different each situation has a different aim or purpose. The foundations of Lean management often shortened to just Lean are built upon removing processes that do not bring value to the end product. The main purpose of Lean management is creating value to the customer by optimizing resources.

It is typically structured around value streams and utilises a layered approach.

3 Lean Process Improvement Concepts Processmaker

3 Lean Process Improvement Concepts Processmaker

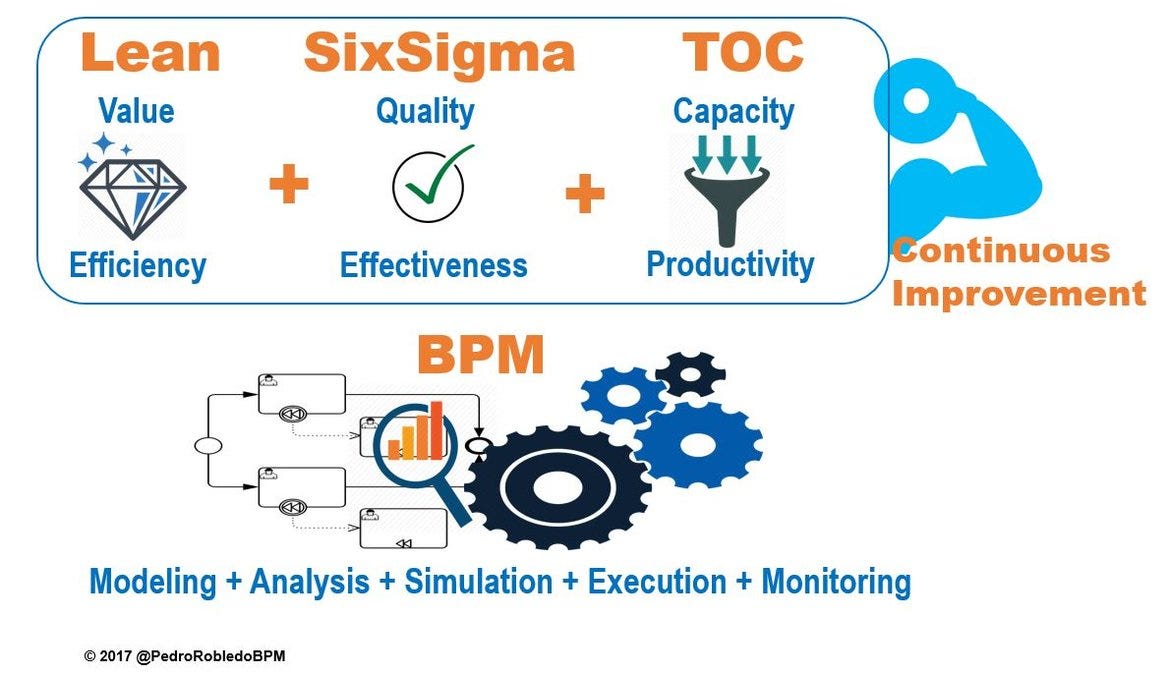

Lean Sixsigma Toc Provide Methods For Continuous Process Improvement In Bpm By Pedro Robledo Medium

Lean Sixsigma Toc Provide Methods For Continuous Process Improvement In Bpm By Pedro Robledo Medium

Bpm Voices Bpm And Lean A Powerful Combination For Process Improvement Lean Six Sigma Lean Sigma Process Improvement

Bpm Voices Bpm And Lean A Powerful Combination For Process Improvement Lean Six Sigma Lean Sigma Process Improvement

What Is Lean Management Definition Benefits

What Is Lean Management Definition Benefits

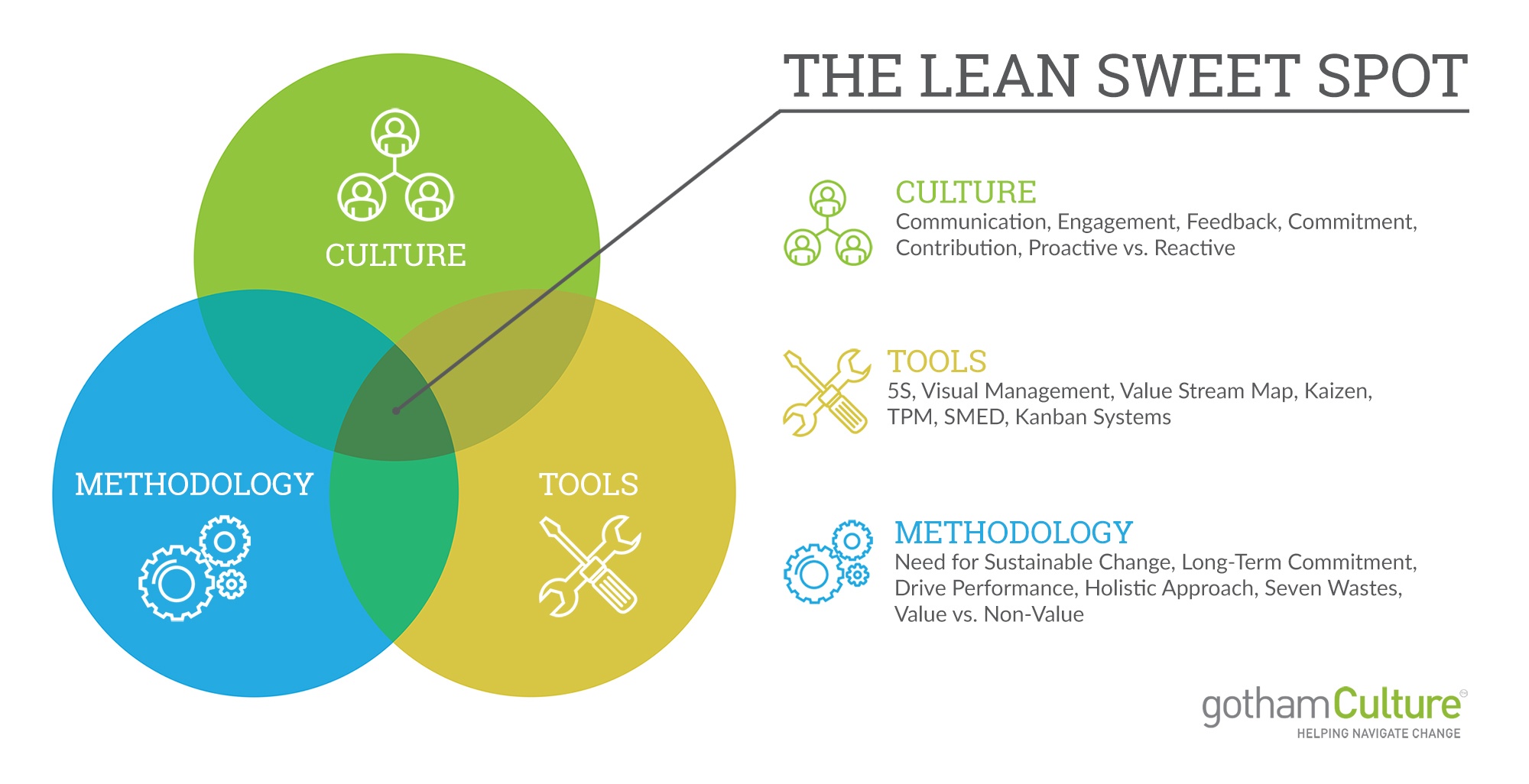

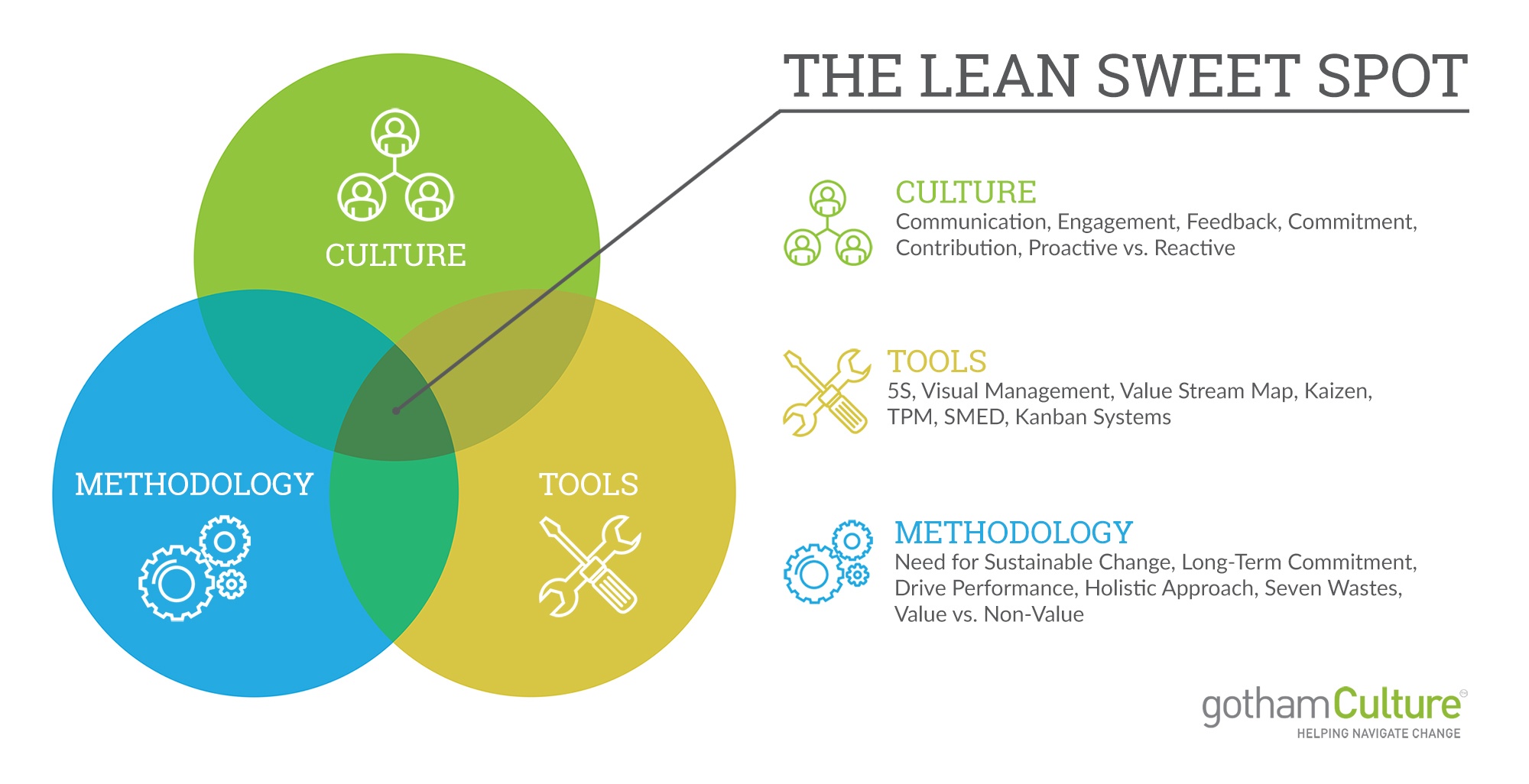

Business Process Improvement Lean Gothamculture

Business Process Improvement Lean Gothamculture

Gillinder Glass Implements Lean Manufacturing For Process Improvement Glassonline Com The World S Leading Glass Industry Website

Gillinder Glass Implements Lean Manufacturing For Process Improvement Glassonline Com The World S Leading Glass Industry Website

3 Key Concepts Of Lean Process Improvement Planview

3 Key Concepts Of Lean Process Improvement Planview

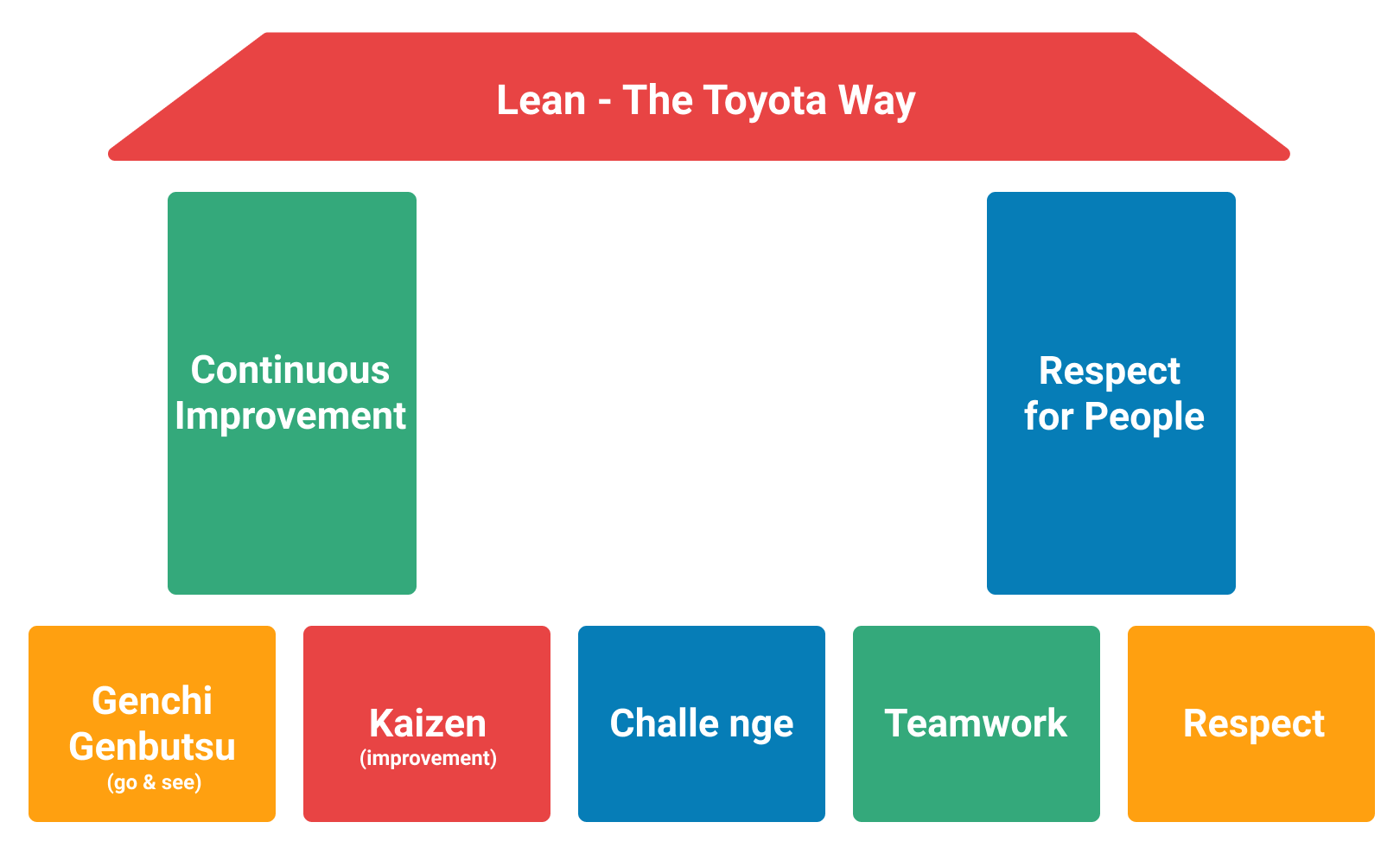

Pelatihan Lean Services Management Implementing The Toyota Way In Services Industry

Explaining The 5s Methodology Change Management Lean Six Sigma Business Management

Explaining The 5s Methodology Change Management Lean Six Sigma Business Management

Lean Process Improvement Stellar Consulting Training

Lean Process Improvement Stellar Consulting Training

What Is Lean Management Definition Benefits

What Is Lean Management Definition Benefits

What Is Lean Management Lean Management Principles

No comments:

Post a Comment

Note: only a member of this blog may post a comment.